TURBIDITY MONITORING SYSTEM (TMS)

General:

Innerspace has developed and offers a turnkey turbidity monitoring system (TMS) for the dredging of contaminated sediments such as PCB’s, or any project where down river/ down current migration of bottom sediments is undesirable.

The initial installation was in Lake Champlain for PCB dredging by Sevenson Environmental Services. With contaminated sediments, it is important that the bottom material is not stirred up, put into suspension and allowed to migrate out of the immediate dredge area. The Innerspace TMS monitors a number of turbidity sensors mounted on the dredge and moored in the surrounding area. A central computer onshore interrogates the remote turbidity stations one at a time, automatically, at a pre-selected rate. The received data, turbidity and battery condition, are displayed on screen and logged to a disk file on a continuous basis. An alarm is displayed, logged and sounded if predetermined turbidity levels are exceeded.

While the number of turbidity stations might vary from project to project, a typical deployed system consists of five strategically placed turbidity meters with solar panels, Innerspace 453A coded RF modem with 8 bit micro controller/digitizer, battery charger controller, cables and complete mounting hardware.

The shore station consists a of an Innerspace 453A RF Modem, laptop Pentium computer, Innerspace TMS software and system cables.

With installation and training provided by Innerspace, the system is truly a turnkey environmental dredge monitoring system.

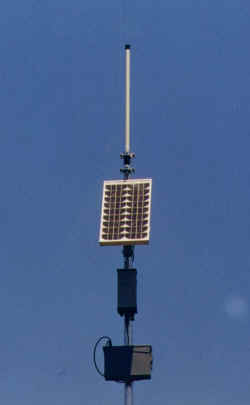

TURBIDITY MEASURING STATION

Consisting of: RF Antenna, Solar Panel, 453A RF Modem, Battery/Charger Assembly, Mounting Pole and Turbidity Sensor (not shown)

Description

Consisting of: Solar Cell, Rechargeable Battery, Coded RF Modem with 8 bit micro controller/digitizer, RF Antenna, Turbidity Sensor and Pole Assembly (Buoy Mount Optional)

The turbidity sensor uses infrared technology and measures in Nephelometric Turbidity Units (NTU). In the pole mounted configuration (shown in photo) the turbidity sensor is protected inside the adjustable section of aluminum pipe. A cut out in the pipe allows the sensor access to the water.

Each station is a complete assembly and any number of stations can be used on a job site. Each RF modem (radio link) is coded so each station in an array can be interrogated, monitored and identified remotely from shore by its own unique code. The station is designed to operate on a 24 hour basis with very low maintenance requirements.

Turbidity Station – insitu

TMS DREDGE GRAPHICS SUB-SYSTEM

General

While TMS can be used for any turbidity monitoring application, it is most applicable to dredging projects because of its real-time operation and display during ongoing dredging. For applications other than dredging, a simpler turbidity storage device could be used whereby the data is collected over time and retrieved or downloaded at any convenient time. Real-time access to the data would usually not be required for non-dredging applications.

Description

When using TMS for dredging applications, a separate dredge graphics system is available to provide precise position and attitude of the dredge and to graphically display digging operations along with turbidity in real-time. This system consists of two Trimble AgGPS 132 sub-meter GPS receivers, DC power supply, Pentium computer, Windows operating system, SVGA monitor, dredge graphics software, turbidity sensors and mounting hardware.

Sevenson Environmental Dredges on site – Lake Champlain

Components of Hazardous Waste Processing Plant

Operated by Sevenson Environmental

Lake Champlain Area – New York State